Machine Stable is an authorized distributor of the DEVELON brand under HD Hyundai.

Understanding Wheeled Excavator Road Operations and Technical Standards

With the continuous advancement of global infrastructure construction, the application scenarios of construction machinery are gradually expanding from enclosed construction sites to urban roads and public areas. In particular, the wheeled excavator, with its high mobility and rapid relocation capability, has become an essential machine for municipal projects, urban landscaping, road maintenance, and emergency repairs. As an engineer with extensive experience in construction machinery operations, I will combine real case studies, technical parameters, and regulatory requirements to systematically analyze the road performance of wheeled excavators, the types of construction machinery that can be driven directly on roads, and best operational practices, providing practical guidance for contractors, equipment operators, and rental companies.

1. Road Performance Analysis of Wheeled Excavators

1.1 Basic Characteristics

The main difference between wheeled excavators and tracked excavators lies in tire-based mobility, which directly provides road adaptability and operational flexibility in urban construction. Key characteristics include:

- Low ground pressure: Prevents damage to paved roads and is suitable for urban streets and residential projects.

- Zero-turn capability: Can complete 360° rotation in narrow construction areas, allowing precise operations.

- Speed and suspension system: Most models have a top speed of 25–40 km/h, with high-end models optionally equipped with high-speed transmissions for short-distance autonomous relocation.

Case Study: In a residential pipeline renovation project in Shanghai, a mini wheeled excavator completed excavation in narrow alleys. Its relocation efficiency was approximately 30% higher than comparable tracked excavators, without damaging the road surface.

| Feature | Description | Advantage |

|---|---|---|

| Ground Pressure | ≤0.8 kg/cm² | Protects roads, reduces damage |

| Turning Capability | Zero-turn | High maneuverability |

| Travel Speed | 25–40 km/h | Fast relocation |

Additionally, small wheeled excavator models perform well in landscaping and residential projects, efficiently completing tree pit leveling, light foundation excavation, and pipeline installation.

1.2 Technical Evaluation for Road Use

To operate legally on public roads, wheeled excavators must meet requirements in power, noise, safety, and dimensions:

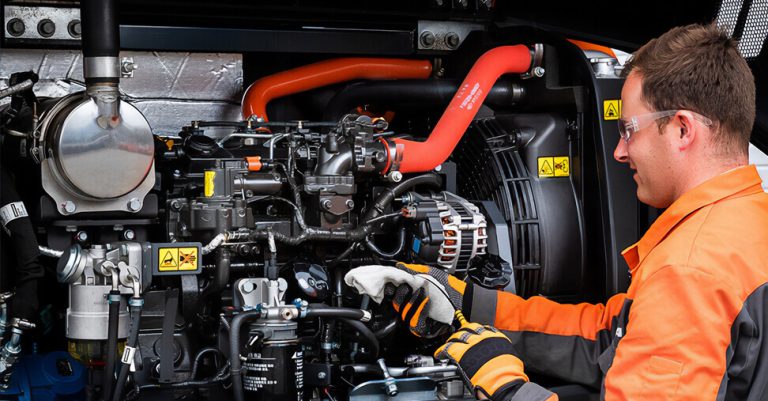

- Powertrain Compliance: Emission standards must meet US Tier 4 Final or EU Stage V and be equipped with DPF and SCR after-treatment systems. mini excavator on wheels typically uses a small diesel engine but still requires emission certification documents.

- Noise Restrictions: Must comply with ISO 6393/6395 standards. Night operations require additional noise reduction measures, such as mufflers and rubber tires. compact wheeled excavator can effectively reduce noise in residential areas.

- Safety Equipment: Complete lighting systems (headlights, brake lights, turn signals, hazard lights), braking systems conforming to ISO 3450:2011, and SAE J1082 rearview mirrors ensure no blind spots. moving excavator with wheels can add backup radar and cameras to enhance operational safety.

- Dimensions and Weight Restrictions: Maximum width generally ≤2.55 m, maximum height ≤4 m; most wheeled excavators naturally comply. Axle loads must be checked according to bridge limits, and some regions require weight distribution documentation. excavator wheels must be selected according to regulatory specifications to ensure stability.

1.3 Typical Regional Regulations

| Region | Regulation | Key Requirements | Example Machine |

|---|---|---|---|

| North America | DOT | Reflective markings, slow-moving vehicle triangle, tail lights; operator license required | wheeled excavator rental |

| EU | CE 2006/42/EC | Tail lights, horn, electronic stability, ROPS/FOPS certification | mini wheel excavator |

| Southeast Asia | Temporary Permit | Road registration, limited-time operation, night driving prohibited | wheel excavator for sale |

| Australia | HVNL | Axle load distribution, size control, road access permit | small wheeled excavator |

| Latin America | National Traffic Standards | Lighting, operator license, special permits for over-limit | mini excavator on wheels |

Practical Experience: In a municipal project in Mexico, using a mini wheel excavator, temporary permits and slow-moving vehicle signs were applied in advance to ensure legal road operation and avoid fines.

2. Construction Machinery Types That Can Be Driven Directly on Roads

2.1 Classification Standards

- Full-road-right machines: Graders, pneumatic rollers, high-speed wheeled loaders; have full road operation capability without additional permits.

- Restricted-road-right machines: Concrete pumps, towable pavers; require temporary permits and restricted operating times/routes.

- Non-road machines: Tracked excavators, large crawler cranes; must be transported via trailers and cannot operate directly on roads.

Key certifications: DOT/ECE lighting system, ROPS/FOPS cabin certification, SAE J1378 hydraulic system protection. wheel excavator for sale usually comes with documentation for legal road operation.

2.2 Typical Road-Eligible Machines

- Asphalt pavers, pneumatic rollers (automatic foldable warning frames)

- Multi-function wheeled loaders (high-speed gears, road tires)

- Telescopic forklifts (ISO 5006 operator visibility standard)

- mini wheeled excavator can operate on roads in residential projects if lighting and warning signs are installed

2.3 Modification and Compliance Path

- Certification by third-party institutions (e.g., TÜV, Intertek) for post-modification safety

- OEM-provided road adaptation kits including lighting packages, reflective strips, and hydraulic speed limiters

- Special modifications: ABS, tire pressure monitoring, electronic speed control

- moving excavator with wheels can improve urban road adaptability through modifications and reduce regulatory risks

3. Best Practices for Road Operation

3.1 Preparation Before Operation

- Essential documents: vehicle registration, road liability insurance, operator compliance license

- Route survey: evaluate height limits, bridge load capacities, and sharp curve radii

- mini excavator on wheels must undergo on-site road inspection before moving between sites

3.2 On-Road Management

- Convoy operation: lead vehicle guidance, rear vehicle support, equipped with emergency warning lights

- Daytime: use red flags; night: LED light strips for visibility

- small wheeled excavator should maintain moderate speed on highways or urban roads to prevent tire overheating

3.3 Emergency Plan

- Fault handling: place triangular warning signs approximately 100 meters ahead and behind the equipment

- Reporting mechanism: contact traffic authorities and submit temporary change applications in case of road closure or failure

- mini wheel excavator can be quickly relocated to a safe area in case of mechanical failure, avoiding traffic obstruction

4. Case Studies and Experience Summary

- Urban Landscaping Projects: Using compact wheeled excavator to quickly complete earthwork in residential areas, demonstrating high maneuverability and minimal pavement damage.

- Municipal Emergency Repairs: Using wheeled excavator rental for pipeline burst repair, completing short-distance relocation quickly, with LED warnings and temporary road permits.

- Long-Distance Road Transport: Selecting compliant excavator wheels and equipping ABS and tire pressure monitoring systems improves safety.

Experience Summary: Proper route planning, legal modification, and compliance with local regulations can significantly improve efficiency and reduce operational risks when using wheeled excavators for road relocation and urban construction.