Machine Stable is an authorized distributor of the DEVELON brand under HD Hyundai.

Improving Mining Transport Efficiency: Lessons from Wide-Body Dump Truck Operations

Over the past decade, I have been on mining sites almost every day. Whether in the scorching summer or the freezing winter nights, the roar of machinery has always accompanied me. As an engineer specializing in mining transport equipment, I have witnessed firsthand how wide-body dump trucks have grown from new equipment into the core of mining transportation. This article combines real cases, operational data, and frontline experience to objectively analyze the application value and technical advantages of wide-body dump trucks in mining areas.

From Road Dump Trucks to Mining-Wide Revolution

Initially, mining transport relied mainly on modified road dump trucks, which suffered from low load capacity, short lifespan, and poor safety. As open-pit mines expanded, the demand for short-distance, high-load transport increased. This is when the concept of off highway dump truck was formally introduced.

These off-highway trucks feature extra-wide chassis, heavy-duty axles, and reinforced frames, designed for the complex terrain of mines. Compared with traditional vehicles, a single trip can increase transport volume by over 40%, reducing the number of drivers needed and saving fuel costs.

Structural Design and Performance Analysis of Wide-Body Dump Trucks

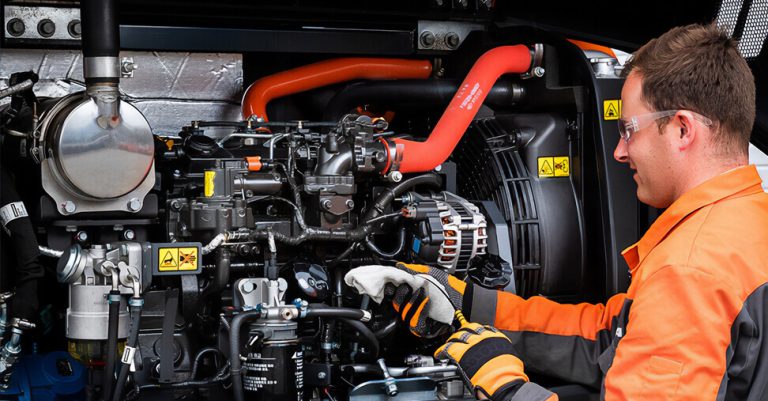

Mining environments are harsh, requiring high structural and power system standards.

“The simpler the design, the better it can handle tough conditions.”

— From my repeated vehicle tests.

The following table compares wide-body dump trucks with conventional road dump trucks:

| Comparison | Wide-Body Dump Truck | Road Dump Truck |

|---|---|---|

| Purpose | Off-highway transport (mining) | Road transport |

| Load Capacity | 70–90 tons | 30–40 tons |

| Frame Strength | High-strength welded | Standard steel |

| Suspension | Mining-strengthened suspension | Leaf springs |

| Safety | High rollover resistance | Average stability |

| Trip Distance | Short-distance, high-frequency | Medium-long distance |

| Cost Efficiency | High initial cost, low operating cost | Low initial cost, high maintenance cost |

Wide-body dump trucks come in various types, such as off highway trucks and rock quarry dump truck, meeting different mining transport needs.

Field Case Study: Performance of Wide-Body Dump Trucks

In a coal mine project in Inner Mongolia where I participated, several 90-ton trucks were deployed, and transport efficiency increased by about 47% within the first three months. In such conditions, the advantages of rock dump truck are particularly evident, providing stable operation on unpaved roads and handling high-frequency full-load trips. Drivers often say: “These trucks are rooted in the rocks, unlike road trucks.”

Technical Highlights: Balancing Load Capacity and Safety

Wide-body dump trucks’ technical advantages include:

High Load Capacity: Reinforced frame and mining-specific axles ensure strong load handling.

Powerful Performance: High-torque engines paired with heavy-duty transmissions enable smooth full-load climbs.

Reliable Hydraulic System: Develon hydraulic lifting system ensures smooth dumping.

Safety and Comfort: Wide cabs and anti-rollover design reduce driver fatigue.

For example, at a copper mine in Yunnan, several rear dump truck models operated steadily on muddy slopes during heavy rain, whereas traditional vehicles often got stuck.

Operational Efficiency: Improving Mine Transport Productivity

Transport efficiency directly impacts mining costs. Comparative analysis shows:

| Vehicle Type | Single Trip Load | Daily Trips | Total Daily Volume |

|---|---|---|---|

| Wide-Body Dump Truck | 90 tons | 15 trips | 1350 tons |

| Conventional Dump Truck | 45 tons | 18 trips | 810 tons |

Wide-body dump trucks can achieve approximately 67% capacity improvement, reducing drivers and labor costs. In narrow or complex mining terrain, articulated dump truck models offer higher maneuverability and improved operational efficiency.

Safety and Stability: The Baseline for Mine Transport

Mines often have steep slopes and rough roads, making safety critical. Wide-body dump trucks include multiple safety features:

Electronic Brake Assist (EBS)

Hill-start control

Dual-circuit brake redundancy

Tilt angle warning system

Field experience shows that articulated haul truck models effectively reduce rollover incidents and maintain maneuverability in narrow mining areas. Additionally, quarry trucks with high-load frames and stable suspension ensure safe continuous operation.

Power and Handling: Navigating Complex Mine Terrain

Different minerals require different power specifications. High-density ores demand strong traction.

Wide-body dump trucks with high gear ratio axles and high-torque transmissions enable smooth full-load climbs.

In quarries and pits, heavy duty dump trucks offer stable load-bearing and excellent passability, ensuring smooth transport.

Field Operations: Insights from Drivers

New operators often worry about complexity, but after training, feedback is consistently positive:

wide visibility, high stability, and ease of operation.

Modular design makes hydraulic, suspension, and brake systems easy to maintain. Average maintenance time decreased from 6 hours to 3 hours, improving uptime. rock hauler truck durability is remarkable, maintaining stable performance even during consecutive heavy-load operations.

Economic Analysis: Long-Term Costs and Benefits

Although wide-body dump trucks have high purchase costs, their high uptime, low fuel consumption, and reduced labor result in significant cost advantages:

| Cost Category | Wide-Body Dump Truck | Conventional Dump Truck |

|---|---|---|

| Initial Cost | High | Low |

| Fuel Cost | Low (~18% savings) | High |

| Maintenance | Medium | High |

| Drivers | Fewer | More |

| Overall Cost Efficiency | Excellent | Average |

This is why wide-body dump trucks are widely adopted in mining operations.

Future Trends: Intelligent and Green Mining Transport

With mine digitalization and green initiatives, autonomous and electric trucks are becoming trends. Some wide-body dump trucks adopt hybrid power systems to reduce fuel consumption and emissions. Intelligent dispatch systems optimize transport schedules based on road conditions and load, ensuring efficient and safe operations.

Professionalism and Industry Culture: Core Value of Mining Transport

As a frontline practitioner, I deeply understand the importance of drivers, maintenance personnel, and dispatchers in mining operations. At a project in Xinjiang, I saw a rock hauler truck operate steadily in freezing night conditions. This experience made me realize: wide-body dump trucks are not just tools; they are the backbone of mining transport.

Conclusion: Balancing Efficiency, Safety, and Responsibility

The adoption of wide-body dump trucks enhances production efficiency, safety, and environmental standards. They mark the transformation of mining transport from “human-driven” to “system-driven,” forming a vital component of modern intelligent mining.

“Technological progress makes the transport of every ton of ore more efficient and safer.”

If your company is considering upgrading mining transport equipment or wants to explore wide-body dump truck options for different capacities,